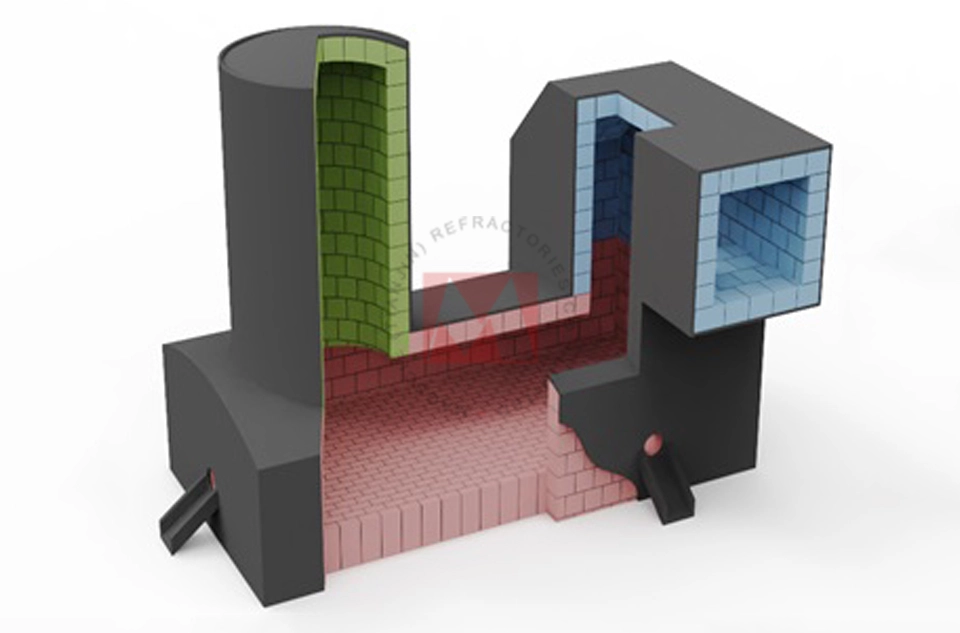

Reactor: is Flash Smelting Furnace most important working area and also the worst working conditions area, dried material and preheated air through concentrate nozzle mixing and high-speed spray into reactor, temperature reaches 1500℃ for desulphurization, smelting, slag making reactions and down to the settling hearth for further completion of slag making process, reaction produced matte and liquid slag are settling at the hearth as molten layers. Refractories working lining under over heat damage, unstable oxidation-reduction chemical atmosphere damage, copper slag sulphide, matte penetration etc. chemical attacks, vigorous erosion and severe temperature change damages. High grade refractories DMK and RMK Products are recommended for reactor working linings.

Settling Hearth: always being damaged by matte penetrating, strong slag attack reaction damages, gas flow erosions. Medium grade DMK and RMK Products are recommended.

Exhaust air duct: exhaust air of all types from copper smelting has rigorous erosion to refractories linings. MAGSCIE recommends ordinary DMK as exhaust air duct working linings.