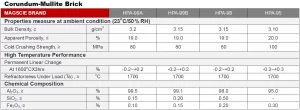

These bricks contain tabular alumina as the base grain and may include various fine materials such as calcined alumina, clay and fine silica. As these bricks generally have low impurity levels, alumina and silica typically make up 99% of the chemical composition. Usually, the only mineral phases present are corundum and mullite. Properties such as high hot strength, creep and slag resistance benefit from this purity level.

HPA (High Purity Corundum Brick) made primarily of alumina under medium to high temperature burning, HPA has advantages such as high purity, strength, chemical stability and corrosion resistance. It was widely used as internal lining of petrochemical and instrument equipment such as ammonia gasifier, ethylene gasifier and carbon black reactor, in which high temperature, pressure, chemical corrosion and mechanical abrasion is encountered.