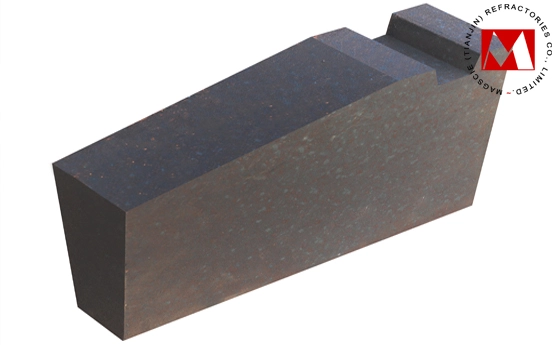

RMK made of fused mag-chrome, magnesite and chromite, processed by ultra-high temperature firing. With properties of very good thermal shock stability, oxidation-reduction resistance, thermal fatigue resistance, wear resistance and erosion resistance. Especially with ultra-strong resistance to slag attack and vacuum damage. Under vacuum refining condition, or strong oxidation atmosphere, or ultra-high temperature liquid erosion, or high alkaline slag and frequent alkalinity changes slag attacks. They are proved to be the irreplaceable, the longest service life and the most economical furnace lining refractories.

RMK are widely used in the vacuum refining furnaces (e.g. RH degasser, VOD degassing ladles), Argon Oxygen Refining Furnaces (e.g. AOD Converters), ultra-high power EAF furnace, non-ferrous smelting big furnaces (IC3 Refining Converters, Pierce Smith Converters, Noranda Furnaces, Outokumpu Flash Smelting Furnaces), or used at key parts of refining furnaces under very harsh conditions, e.g. Working linings, hot spots, slag line zone, tuyere zone, erosion zone and easily damaged parts of big furnaces. (DA means Impregnation process)

After Impregnation process treatment, the physical and chemical properties of RBK are greatly improved. The porosity will be reduced by 7%, the bulk density will increase by 0.05g/cm3, and the Cold Crushing Strength will increase by about 30MPa. This is an additional procedure.