Using high-purity ceramic fiber cotton as raw material, with patented formula, our self-develop environment-friendly production equipment was used to form the high quality inorganic board without secondary calcination.

Characteristic:The new inorganic ceramic fiber board contains very low organic matter. It will be smokeless, tasteless, and its strength and hardness can increase when exposed to naked fire and high temperature.

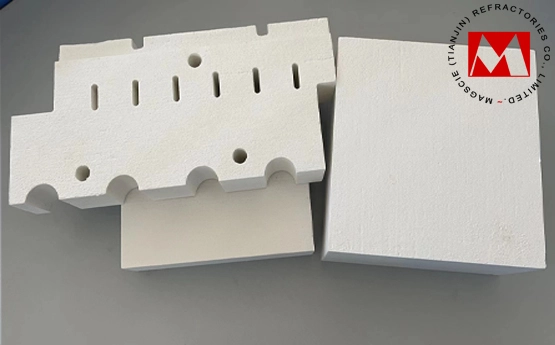

With the use of new equipment, production technology and formula, the new inorganic ceramic board has more accurate size, more delicate and smooth surface, extremely low shot content, low thermal conductivity and small thermal shrinkage.

It can be cut into corresponding size according to the use requirements. And can be processed by drilling and cutting. It is an ideal environmental protection high temperature resistant insulation panels for wall hanging furnace, electric furnace, oven, etc.

Application:

> Be thermal insulation and fire-retardant materials for metallurgy, petrochemical, glass, ceramics, non-ferrous metals and other industries.

> Use for environments with special requirements, such as required smokeless and fire-free in high temperature or naked flame.

Five significant advantages:

1.5mm-200mm thickness, one-stage moulding

The size of traditional organic fiber board is 10mm-60mm, thinner one is fragile and has no strength, while thicker one is hard to dry and easy to moldy deformation as “cotton core”.

Non-calcined inorganic ceramic fiber board has excellent characteristics, such as high density and easy to dry, to make sure the high quality of fiber board while extremely thinner or thicker without deformation.

2.Extremely low organic content, <1.45%

The organic content of traditional organic fiber board is 7-9%, it can absorb moisture mildew easily, fire and smoke in higher temperature.

Non-calcined inorganic ceramic fiber board make use of high quality inorganic glue to achieve extremely low organic content, while avoid the problem of fire and smoke when using fiber board.

3.No calcination, smokeless, tasteless and colorless in higher temperature

If the traditional organic fiber board want to be smokeless and tasteless in higher temperature, it must be calcined twice and dipped again after moulded, these stages may cause the organic content is still very high, while the internal strength of the fiber board can not be guaranteed.

Non-calcined inorganic ceramic fiber board can be formed to one-stage moulding without secondary calcination by using high quality inorganic glue, which can be really smokeless, tasteless and colorless.

4.Higher strength, carving freely

Due to the characteristics of silica sol binder, the traditional organic fiber board can’t form high-density fiber board with one-stage moulding. The internal strength of fiber board can’t be guaranteed because it has to be dipped again after moulded.

Non-calcined inorganic ceramic fiber board can be formed to one-stage moulding and achieve the density of 400 or above. It has the same strength in the internal and external, and can be carved into any desired shape freely.

5.No mildew, no waste water, environmental protection and energy saving

The traditional organic fiber board is easy to mildew because of starch using, and produce lots of poisonous waste water that inevitably polluting the environment.

Non-calcined inorganic ceramic fiber board will not produce waste water, cyclic utilization, truly achieve environmental protection and energy saving, while contributing to the cause of human progress.