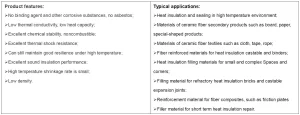

The product has light weight, high temperature resistance, good thermal stability, low thermal conductivity, low heat and mechanical shock resistance and other advantages, product than insulating brick with traditional casting materials such as refractory material and energy saving up to 10-30%.

MWOOL are chemically stable and resistant to most aggressive chemicals (except phosphoric acid, hydrofluoric acid and strong bases). Even if the product is soaked by oil, water or steam, its physical properties such as temperature resistance and heat insulation will not change.

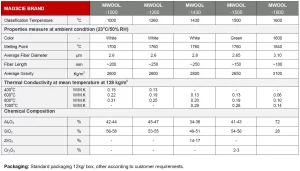

MWOOL-1000,1260,1430: Ceramic fiber is a kind of melting method to produce amorphous (glass) of lightweight refractory fiber material, its production process is the different levels of Al-Si with raw material in electric arc furnace melting, after spun into different temperature of Al-Si ceramic fiber, product category temperature of 1000℃ to 1430℃.

MWOOL-1600: Polycrystalline mullite fiber is the latest ultra-light high-temperature refractory fiber at domestic and abroad, classification of the temperature of 1600℃ and the melting point 1840℃. It is a unique polycrystalline refractory fiber in the form of mullite crystal phase. MWOOL-1600 polycrystalline mullite fiber and glass fiber have completely different production process. it is produced by chemical “colloid method”, and its chemically formulated according to the formation of single crystal mullite (Al2O372%+SiO228%). The principle is to make soluble aluminum and silicon into a colloidal solution with a certain viscosity, and then spun into a fibrous embryo body, and then treatment with medium-high temperature and crystallization process to transformed into the main crystal phase of single mullite phase. The fiber diameter is 3-5um, and the length is 10-150mm. The fiber appearance is white, smooth, soft and elastic, like absorbent cotton.